Our Mission

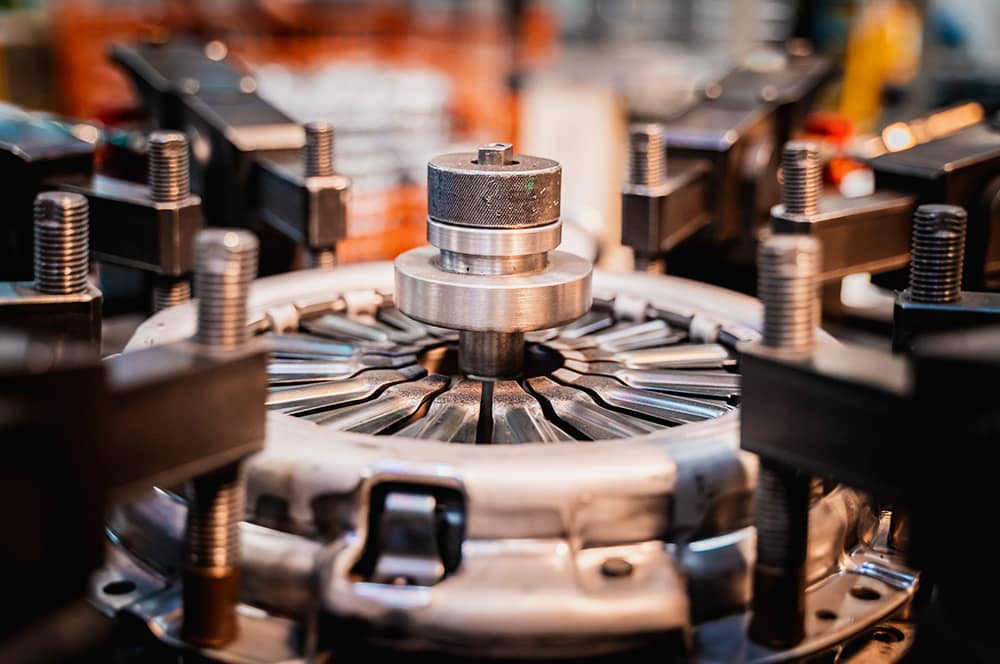

To be an auto parts supplier satisfying our clients, employees, suppliers, and shareholders, through:

- Quality, service, innovation, support and competitive prices.

- Responsibility in relationship management.

- Profitability.

- Protecting the environment and people’s safety.

Our Vision

To become the leading commercial partner and supplier of our customers in auto parts, achieving a permanent growth of our share in the Colombian and foreign markets.

OBJECTIVES OF THE INTEGRAL MANAGEMENT SYSTEM

Bonem S.A., supplier of products for the auto parts and agricultural machinery sectors, is committed to satisfy the needs of its customers, employees and shareholders, taking special interest in protecting the environment, preventing contamination and caring for the physical integrity of its workers, visitors and contractors, by means of:

- Good quality products and services, efficient use of natural resources, reduction in waste generation and prevention of injuries and illnesses.

- Observance and compliance with customer, legal and other stakeholder requirements.

- High levels of technology, productivity, and safety.

- An excellent trained, qualified, and participative human team.

- Continuous improvement as a culture of the people working at Bonem.

Objectives of the integral management system

- CUSTOMER SATISFACTION: Understanding it as the perception they have of the quality of products and services provided by Bonem.

- REDUCTION OF WARRANTY RETURNS: Reflects the ability of our products to meet the functionality expected by the customer.

- ON TIME DELIVERIES: Showing the timely manner in which we send our products so our customers can address their needs.

- EFFICIENT USE OF NATURAL RESOURCES: understood as rationalizing usage of resources and materials, especially drinking water consumption.

- WASTE REDUCTION: reflected in proper use and correct separation of waste to minimize the environmental and economic impact of hazardous waste.

- PREVENTING ACCIDENTS AND INJURIES TO PEOPLE: searching to reduce accident rates in company workers, visitors and contractors.